Projects

Full Automation Upgrade for a Leading Beverage Factory Delivered in Nigeria

One of our recent success stories at IFN Services showcases how a strategic engineering upgrade can transform factory performance within weeks

Conveyor System Upgrade for a Major Biscuit Manufacturing Plant

When conveyor systems fail, the entire production line suffers. A major biscuit manufacturer in Lagos recently faced this exact challenge until they partnered with IFN Services for a complete conveyor system overhaul.

Industrial Pump Overhaul & Flow Optimization for a Dairy Processing Plant

In dairy production, pump systems are the heart of operations responsible for moving milk, cream, yogurt mixes, and cleaning fluids throughout the facility. When pumps fail or operate inefficiently, the entire plant can experience downtime, contamination risks, and inconsistent product flow.

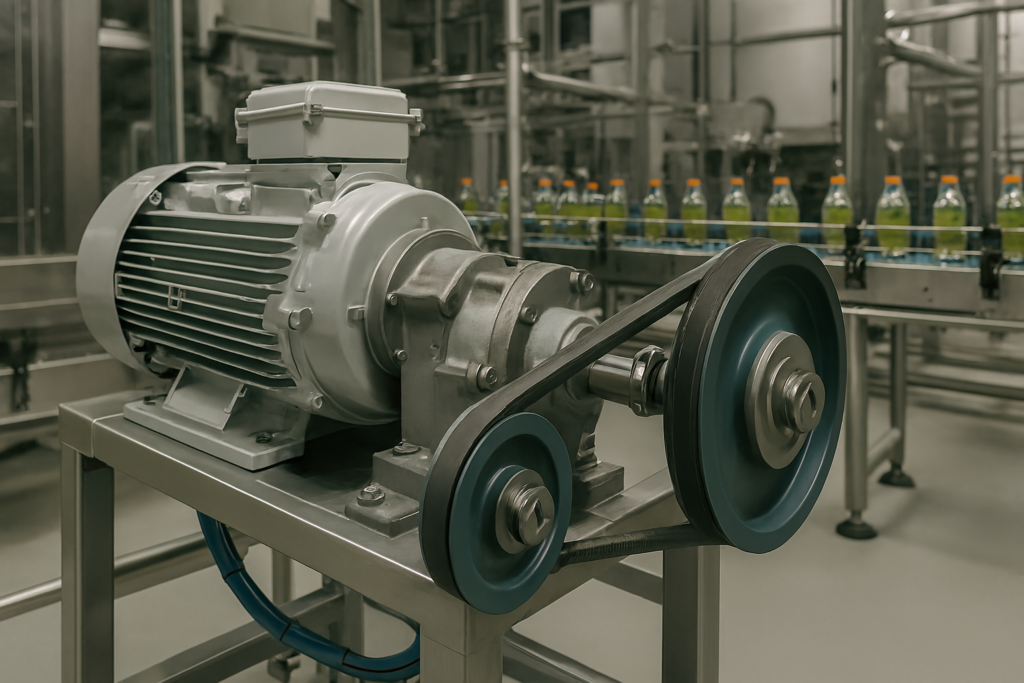

Power Transmission System Upgrade for a Bottled Water Production Plant in Abuja

Power transmission systems are essential in bottled water production, where motors, gearboxes, pulleys, and belts drive critical processes such as bottle molding, filling, capping, and conveyor movement. When these systems underperform, the entire production line experiences delays, breakdowns, and inconsistent performance.

Solar Power Installation & Backup Power Integration for a Food Processing Factory in Kano

Energy instability is one of the biggest challenges for manufacturing companies in Nigeria. Frequent outages, rising diesel costs, and unreliable grid supply often disrupt production and increase operational expenses. A major food processing factory in Kano faced these exact issues.

Industrial Power Backup System Upgrade for Continuous Manufacturing Operations

In today’s modern industrial environment, power reliability is not optional—it is a strategic requirement. Even one minute of downtime can halt production, damage equipment, interrupt supply chains, and cause massive financial losses. For manufacturers in the Food and Beverage sector, the stakes are even higher due to product safety, batch continuity, and strict regulatory standards.